Hot (recycled/ modified) rubberized Asphalt Membrane is designed for use as a waterproofing and roofing membrane, typically on concrete structures in vertical and horizontal applications. It is specially formulated from refined asphalts, synthetic rubber and inert clay filler.

Benefits:

- 100 % solid. No solvent, zero VOC & seamless

- Tough, flexible, self-healing and crack-bridging membrane

- Excellent adhesion to substrate and cohesive strength

- No curing time required and ease of application

- Resistance to acids (fertilizers, building washes, acid rain, etc.), alkali, methane and numerous building wastes

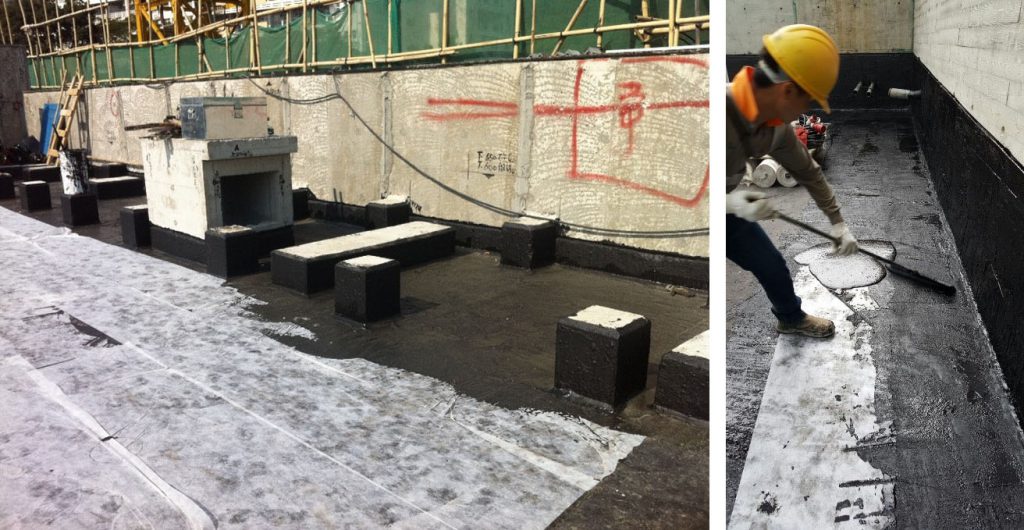

Standard Application:

- Primer coat with bituminous primer

- Melt solid Rubberized Asphalt with double air-jacketed boiler to around 180℃

- Apply first coat of membrane

- Reinforced with proprietary fiber mesh then apply second layer of membrane

- Lay the protection course

Typical Drawings:

- Coming Soon

Product Brand being used:

- HYDROTECH MM6125

- CARLISLE BRAND

- PERMAQUIK BRAND